Reducing Cost of Maintenance Dredging

of a Sea Port

By Implementing

Integrated Basin Management Plan (iBMS)

Successful implementation of Integrated Basin Management System has to potential to reduce the Maintenance Dredging Cost of a Port substantially.

iBMS employs innovative methods using advanced technologies to reduce the yearly cost of maintenance dredging. A unique and port specific HBMS is developed after studying the local topography and characteristics features of the port and nearby water bodies.

Up to 80% Reduction in Maintenance Dredging Cost

Explore Our Innovative Methods and Solve the Economic Woos of Your Organisation

How We Develop and Implement the iBMS ?

Step-1: Study, critically analyse and understand the existing recurrent activities of maintenance dredging . It includes the studying the dump area, types of dredgers used, quantity of dredging, cost per unit, cost calculation etc.

Step-2: Understand the historical time frame and spatial distribution of sedimentation. It includes the study of rheology of sediments.

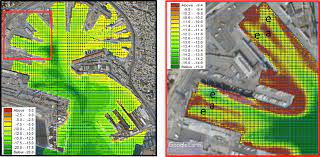

Step-3: Understand the spatial and historical distribution of current and tidal stream patterns. Carry out an hydrodynamics study of the harbor and nearby water bodies to list out the most probable causes of recurrent sedimentation.

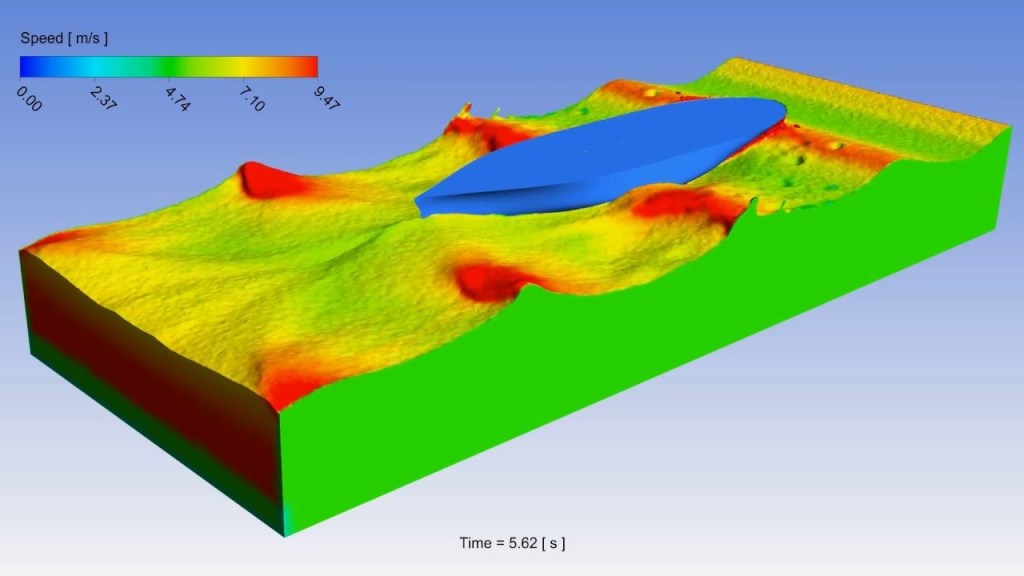

Step-4: Carry out a Computational Fluid Dynamics (CFD) study of the river flow and / or tidal flow as required. Ascertain most probable causes and their intensities of recurrent sedimentation.

Step-5: As per the result of the analysis, develop a best suitable, effective and port specific Integrated Basin Management Plan (iBMS). It employs in-situ sediment barriers of specialized geo-fabrics, deflection barriers, bubble curtains, coagulants, turbidity barriers, sediment tanks, sediment re-suspender and periodic flushing of fresh sediments, and super efficient augur dredgers wherever required. This list is only indicative. Our specialist team knows the best – what to implement and when to implement.

Step-6: Implementing the iBMS would prevent the causes of sedimentation in situ so as to reduce the sediment transport into the harbor. This should reduce sedimentation by 50-80%. It further plans for super cost effective methods of residual dredging to remove the left out sediments.

Step-Z: With iBMS ( integrated basin management System) in place, port operators may invest in capital dredging for Capacity Augmentation which has not been possible due to the scare of the Maintenance Dredging Cost.

What We Use?

Computational Fluid Dynamics Study.

Hydrodynamics Study.

Silt Curtains, Silt fencing, Turbidity curtains.

Bubble Curtains

Developing and implementing iBMS.

Cost effective and innovative Dredging methods.

We work for the future.

With a futuristic look ahead ability, we work hard, we innovate, we use emerging technologies with a view towards sustainability of business, profitability of businesses while taking care of the mother earth. We strive towards greening the future. We contribute towards the Global Green Agenda by cutting emissions and implementing alternate sources of energy.

We are here to stay and cling to the Green Technologies and Green Procedures We will strive towards making the Maritime Industry zero carbon emitting Industry. We are continuously working to innovate new methods, bring in new procedures, new working styles suitable to the future challenges.

Contact Us

To explore our services and contact us

Cost effective, reduced time delays and improving on carbon footprint of industries.

We promote Environmental Conscious Business.

Green Operations and Green Procedures with reduced cost and improved safety standards. We feel concerned and We care for the future.